DFI™

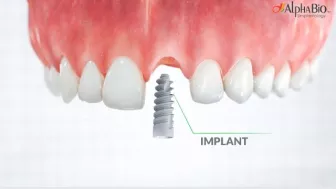

A Cylindrical Implant

you can Rely Upon with Confidence

The DFI™ implant is one of Alpha-Bio Tec.'s Legacy solutions. It is a cylindrical, slightly tapered implant suitable for all bone types & a variety of clinical indications. From a single tooth to full arch restoration, the DFI implant is easily stabilized & controlled during placement & enables you to achieve long term stability, predictable esthetic results & high clinical success rates.

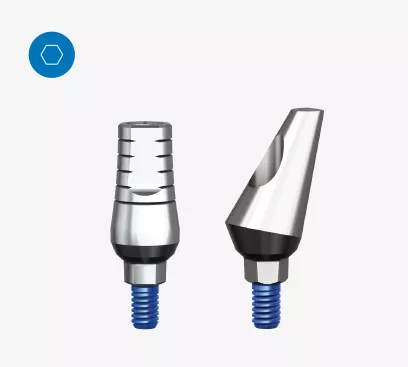

Implant-Abutment Connections:

Conical Standard (CS) | Internal Hex (IH)

DFI at a Glance

Good Primary Stability

Controlled & Smooth Insertion

Large surface area

Slightly Tapered Apex

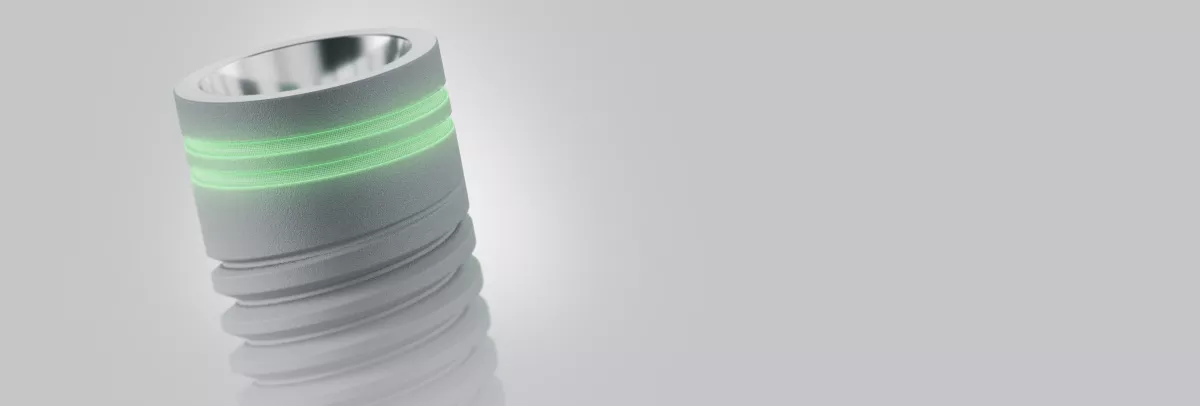

Micro Rings

- Reduced marginal bone loss

- Decreased crestal compression

- Increased Bone to Implant Contact (BIC)

Cylindrical Body

with Variable Threads

- Increased BIC

- Efficient load distribution

- Reduced Marginal bone loss

Slightly Tapered Flat Apex

with Sharp Threads &

a Cutting Flute

- Good primary stability

- Increased surface area

- Smooth & controlled insertion

Implant Dimensions

Please select the implant dimensions of your choice

Related Products

Explore & Discover

Intrudution

MultiNeo Features

Lorem ipsum dolor sit amet

consectetur. Nulla arcu leo enim amet

justo interdum metus eget dignissim.

03:39

Intrudution

MultiNeo Features

Lorem ipsum dolor sit amet

consectetur. Nulla arcu leo enim amet

justo interdum metus eget dignissim.

03:39

Intrudution

MultiNeo Drilling

Protocol

Lorem ipsum dolor sit amet

consectetur. Nulla arcu leo enim amet

justo interdum metus eget dignissim.

03:39

Testimonials

What our customers say about us.

“Using the DFI for 15+ years, in patient follow-up, we’ve seen its performance – high primary stability, and no bone resorption or biomechanical complications.”

“The DFI provides maximum surface area while still remaining passive, and because it’s gentle to the bone, it results in minimal bone loss during implant placement.”

“I use the DFI for cases with hard bone, where its variable threads design enables smooth and seamless insertion with diminished frictional heat.”