Surface Technology

Surface Treatment

for Enhanced Predictability

& Clinical Success

Numerous scientific studies worldwide have proven that implant surface topography is an important factor in achieving osseointegration. Mechanical & chemical surface treatment increase the implant surface area, allowing enhanced bone to implant contact. Clinical research data shows that Alpha-Bio Tec.'s implants achieve clinical success rates of 98.3% & 99.6% in immediate loading procedures.

NiNA™

Surface

Discover a new world

of confidence and

performance

Enhanced bone

attraction

Increased surface

area & BIC

(Bone Implant Contact)

Faster healing

time

NiNA™ is an advanced hydrophilic

surface consisting of multiple levels:

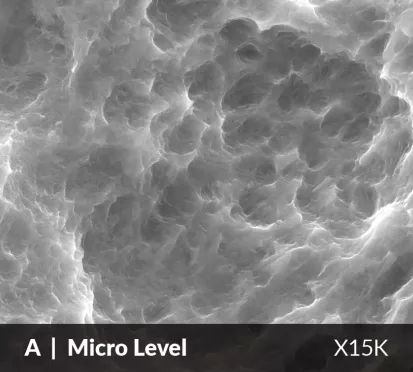

- The basic micron level produced from the known and trusted sandblasted and acid etched treatment

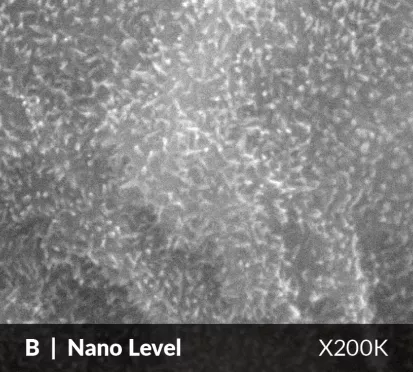

- New innovative TiO2 structures on the nanometric level

- A protective layer deployed on the implant to maintain the Titanium's natural hydrophilic properties

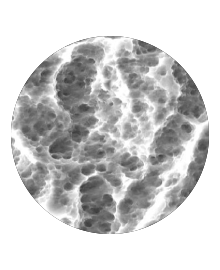

Nanostructures

Visible nanoscale TiO2 structures increase surface area

and actively promote osteoblast bone formation.

The active attraction of osteoblasts, combined with

surface hydrophilicity, enhances a biological response

accelerating wound healing processes.

SEM images of a 15K magnification of a sandblasted and acid-etched implant (A) vs. a 200K magnification

of NiNA surface treatment (B), demonstrating growth of TiO2 structures on the implant surface.

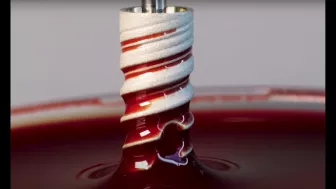

Dry Packaging

Preserved Hydrophilicity at Every Step of the Procedure

The NiNA™ surface technology enables the implant to be delivered in an easy-to-use dry package, designed for maximum comfort and ergonomics.

The dry packaging enables the implant to maintain its hydrophilic properties even when removed from the package.

NEW LAUNCH

MultiNeO™ Powered by NiNA™

Is the synergy between an innovative active implant and

an advanced bioactive NiNA™ surface enabling you to

enhance your clinical performance and confidence in

immediate implant and loading procedures.

Explore

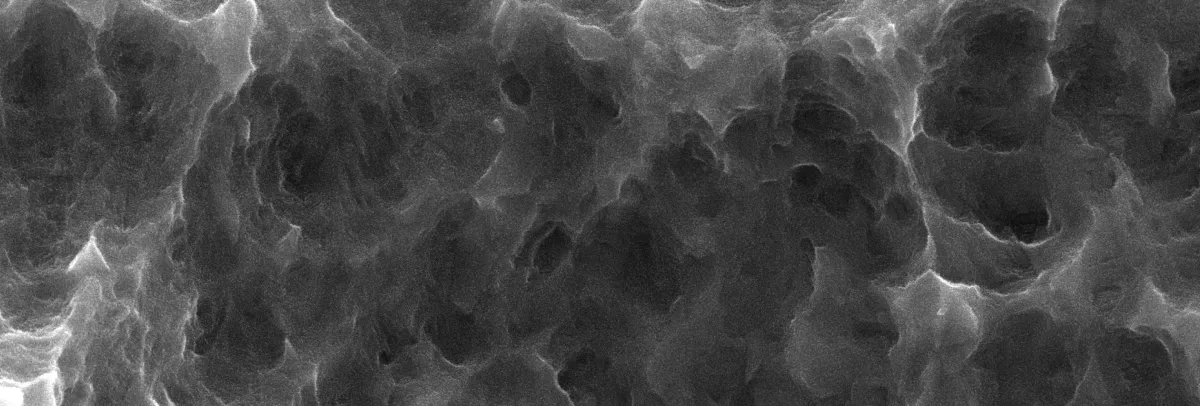

NanoTec™

Discover a new world

of confidence and

performance

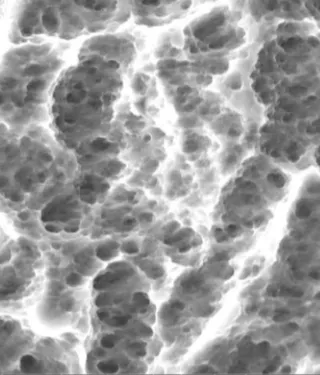

NanoTec™ implant surface is achieved through a mechanical & chemical surface modification process, which involves sandblasting and double thermal acid etching, for the creation of micropores (sized 1-5 microns).

Clinical Features & Benefits

- high surface area differentiation

- Increased blood and plasma proteins absorption into the implant's micropores

- Early osseointegration immediately after placement

- High long-term BIC (Bone to Implant Contact)

- Increased secondary stability

- Higher predictability